Case Studies

TRUCKPAVE – Heavy Vehicle Access (Chadderton)

Overview

Project

Electricity Depot, Chadderton

Client

Electricity North West

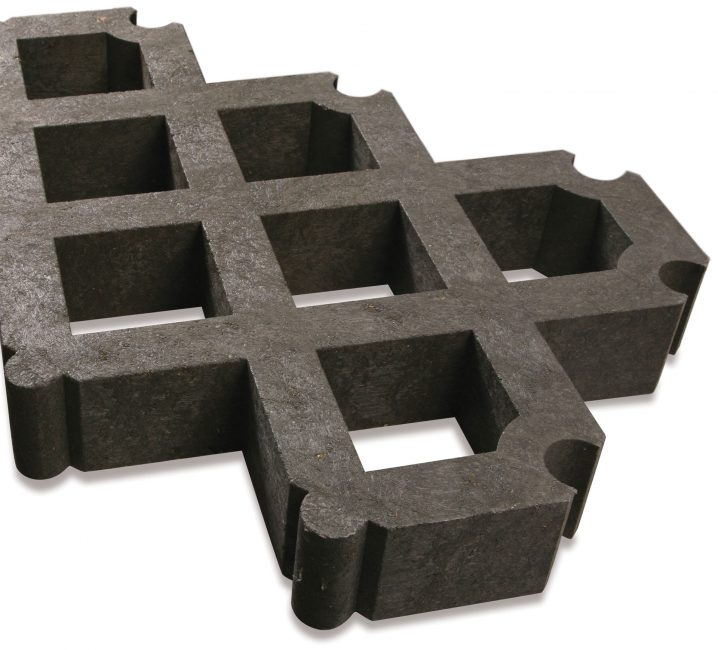

Product

TRUCKPAVE

Product

TRUCKPAVE

Application Function

Ground Stabilisation

Market Sector

Civil Engineering & Building

Product Solutions

TERRAM TRUCKPAVE, laid on a free draining granular stone sub base, was selected as the surface course for this heavily trafficked area, amounting to some 3,700m2. Given the industrial nature of the Electricity North West application, the stone infill option was chosen.

TERRAM TRUCKPAVE provides a permanently stable, robust and durable surface laid on a permeable free draining subbase, achieving a sustainable drainage solution. The paving is flexible and resistant to cracking with high compressive strength, capable of dealing with vehicles up to 60 tonnes gross weight, and 10 tonne wheel loads.

Original &

The Best