FAQs

Frequently Asked Questions

Solving all your questions regarding TERRAM products, sustainability and the brand. For further information and queries please contact us.

Grass Protection

Can GrassProtecta™ be used for heavy good vehicles?

Yes, very occasional HGV parking up to 8t per static axle load on firm to stiff ground.

What is the temperature range for GrassProtecta™ installations?

6 to 25 degrees centigrade.

How does temperature affect GrassProtecta™?

Grassprotecta expands in hot weather and contracts in cold weather. Leave a gap of 1cm between rolls when installing in cold (<10 deg centigrade) weather conditions.

Can I lay turf over the top of the GrassProtecta™?

No, you can lay turf beforehand or use grass seed once Grassprotecta is installed.

Can I use a lawn mower to cut the grass once GrassProtecta™ is installed?

Yes, you can.

How do you cut GrassProtecta™?

With a sharp pair of secateurs.

How long will GrassProtecta™ last?

At least 10 years.

How often can I drive on a grass surface with GrassProtecta™?

Up to 4 days per week.

Can GrassProtecta™ be used on a slope?

Yes, up to 1:20 (5%)

Can I drive on GrassProtecta™ immediately after it’s installed?

Yes but we recommend restricting trafficking until after the grass has thoroughly established through the mesh and the grass has been cut several times.

How soon can I start using GrassProtecta™ once it’s installed?

6 –8 weeks during the growing season but may be longer at other times of the year.

Can GrassProtecta™ be used if the ground is soft & wet?

No, the ground must be firm and well drained.

How many pins do I need for GrassProtecta™, GrassCarpet™ and TurfProtecta™?

There are 50No. pins in a bag. A single roll (2m x 20m) will require a minimum 4 bags (200 pins). Installations of 2 or more rolls will require a minimum of 3 bags (150 pins) per roll plus 1 extra bag.

What grade of GrassProtecta™ do I need?

- Lite: pedestrian, bikes & infrequent cars

- Medium: occasional cars and vans

- Heavy: regular cars and vans

Please see the product selector and SDI guide for more details.

What type of grass mesh (GrassProtecta™ or TurfProtecta™) do I need?

Turfprotecta is a light mesh designed for pedestrian and very occasional light vehicle traffic, the Grassprotecta mesh range is designed for all types off traffic from pedestrian to heavy vehicles. Please see the product selector and SDI guide for more details.

Porous Paving Grids

What markers are available for parking bays?

Snap-fit markers are available for both Bodpave 40 and 85. Different methods for delineating parking bays are available for Truckpave installations including the use of different coloured aggregate and conventional line painting.

What makes Terram Bodpave™/Truckpave™ better than alternatives?

Market leading TERRAM porous paving products have been subjected to rigorous laboratory tests to determine their suitability for use and have been installed on numerous projects throughout the UK for decades with a proven track record. TERRAM provides site specific design advice based upon decades of experience to ensure a successful installation. TERRAM offers impartial design advice and will only suggest the use of porous plastic paving for appropriate projects.

What Porous Paving Grids should I use?

For car parking bays and overspill car parks only, we suggest using Bodpave range. Specifically, Bodpave™ 85 is suitable for car parking bays and occasional HGV overrun. For car parks, HGVs, and coach parking bays, we suggest using Terram Truckpave™.

Please note that Bodpave™ 40 units are generally ideal for car parking bays and overspill car parks. However, for car/coach parking and occasional HGV overrun, we recommend Bodpave™ 85 units. As for Lorry, coach, and car parks, Truckpave™ is the recommended choice. For more detailed information, please consult the Terram technical department.

What vehicle weights will the units support?

All TERRAM Bodpave and Truckpave units can support light vehicles as the gravel or structural soil fill carries most of the load. TERRAM Bodpave 85 and Truckpave units can support occasional and regular HGV overrun respectively. It is more important to consider the dynamic loadings resulting from turning, braking, accelerating and slewing (“dry” steering).

What is compressive strength?

In the context of paving units, compressive strength is a measurement of the maximum load a unit can transmit downwards without breaking or crushing excessively. It is important to apply a factor of safety when comparing the maximum or ultimate compressive strength vs the anticipated loading or the units will deflect excessively.

Is Truckpave™ anti-slip?

The current standard finish on TERRAM Truckpave units has been assessed as low and moderate slip potential in dry and wet conditions respectively. Wet and icy weather conditions, detritus and other contaminants such as spilt oil will increase the slip and skid risk so some ongoing maintenance of a Truckpave surface will be required. Increased friction surface treatments are available on a made to order basis and subject to minimum order quantities.

How do I compact the contents?

For gravel filled units, the specified 4-15mm clean hard angular aggregate should be fairly self-compacting although a single pass with a light vibrating plate machine or roller may be used to firmly bed the pavers and settle the fill. For grass filled units, the cells should be loosely filled with structural soil (rootzone or a friable topsoil with a very high sharp sand content). Excess soil should be removed and a single pass with a light vibrating plate machine or roller may be used to firmly bed the pavers and settle the fill, but do not compact the soil.

How many units of Porous Paving Grids are there per SQM?

- Truckpave – 4.2/SQM (each unit is 40cm x 60cm)

- Bodpave 4.0/SQM (each unit is 50cm x 50cm)

How thick does the subbase of the Porous Paving Grids need to be?

Thickness depends upon the underlying ground strength, type of vehicles and frequency of use. A minimum thickness of 100mm with a stiff biaxial geogrid for residential domestic paths and driveways but may need to be thicker than 400mm for industrial hardstanding for heavy goods vehicles.

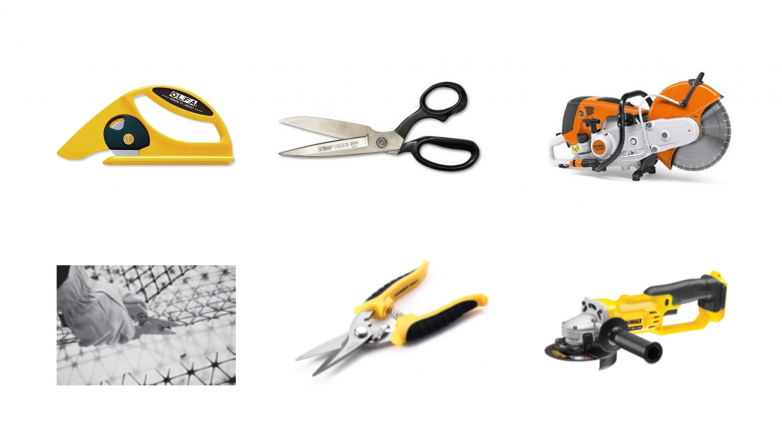

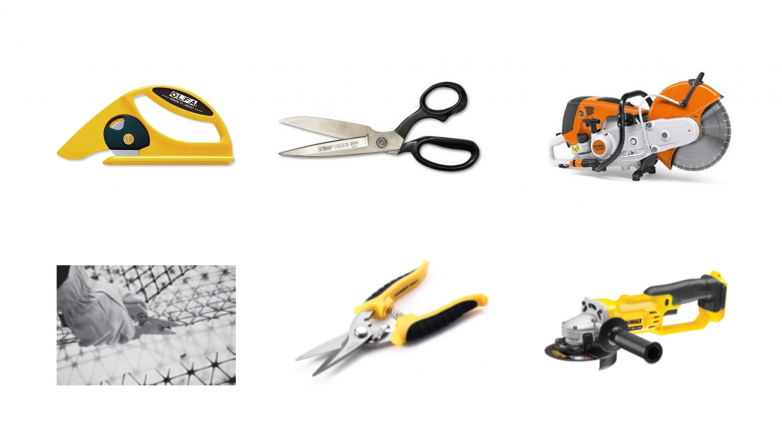

How do I cut the paviours?

Truckpave and Bodpave units can be easily cut by hand or a power saw with a fine-toothed blade.

Can I use turf on Bodpave™?

No. Bodpave units should be filled with a structural growing media such as rootzone and grass seeded.

Can I use Bodpave™ for a turning circle?

No. We suggest that a bound material or concrete block paving is used for surfaces subject to regular turning manoeuvres and/or channelized traffic.

Do I need to use any fixing pins with Porous Paving Grids?

BP85 units have 18No. integral ground spikes per unit (35mm long) to improve shear resistance.

Can the paviours be used on a slope?

Yes, the maximum advised gradient for traffic applications is 12% (1:8) 7º.

Can I use site won topsoil to fill the paviours?

No. A structural soil with a high sand content should be used for the bedding and fill material such as rootzone to ensure good drainage, reduce the risk of compaction and healthy grass growth.

What aggregate do I need for the subbase of Porous Paving Grids?

DoT Type 1 (well graded granular aggregate) with adequate drainage or a modified permeable Type 3 sub-base (coarse or open graded aggregate).

How long will the pavours last? (What is the design life?)

The anticipated service life of Bodpave 40 is 10 years, Bodpave 85 is 20 years, and Truckpave is 60 years. Long term durability will also depend upon the total traffic loading, maintenance and the overall pavement construction.

Can Truckpave™ or Bodpave™ units be recycled?

Yes, both Truckpave and Bodpave units are made from polymers that can be recycled.

Do I need a subbase for Porous Paving Grids?

Yes, a Bodpave or Truckpave surface requires a strong stable base to transfer vehicle loads and limit settlement. It may not be necessary to construct a new subbase if the existing ground is sufficiently strong enough for example when surfacing an unpaved hardstanding.

What type of stone (gravel) do I need to fill the paviours?

A 4-15mm clean, angular aggregate (BS EN 13242) made from a hard preferably igneous rock such as granite or basalt. Rounded and semi-rounded gravels such as pea shingle are not suitable.

Geotextiles

Do you supply all rail drainage products?

Our distribution partners supply all rail drainage products including TERRAM geosynthetic materials. Please contact us for their contact details.

What are PADS numbers?

PADS (Parts and Drawing System) is Network Rail’s database of accepted products with numbers allocated to individual items or parts.

Are Terram products approved by Network Rail and TFL?

All TERRAM PW (Permanent Way), Standard Geotextiles hold Network Rail Acceptance certificates and have associated PADS numbers. TFL (Transport for London) and Network Rail require that all suppliers use of a qualification scheme called RISQS (Railway Industry Supplier Qualification Scheme). TERRAM (trading as Fiberweb Geosynthetics Ltd, part of the Berry Group) are registered with RISQS.

How do we cut the material of Rail Geosynthetics?

A4 Single layers of most TERRAM geosynthetic materials can be cut with sharp scissors or safety knives although regular changes of blades will be needed for long lengths. TERRAM Geocomposites such as PW4LA incorporate a reinforcing geogrid. The ribs of the geogrid mesh are square edged and up to 4mm thick, they can be cut with sharp shears or a disk cutter/angle grinder. Rolls can be trimmed with a petrol cut-off saw but suitable precautions should be taken to ensure the safety of the saw user and others in the vicinity. Wear appropriate personal protective equipment such as gloves and eye protection.

Do we overlap the material of Rail Geosynthetics?

The minimum overlap is 300mm but may be as much as 1.5m depending upon the ground conditions and product being installed. Please refer to the Network Rail Certificate of Acceptance and/or TERRAM specification, design and installation guidance for more details.

How wide are the rolls of Rail Geosynthetics?

TERRAM PW (Permanent Way) range varies between 1.9m and 4.0m wide. TERRAM standard geotextiles used for drainage trench lining (used alongside track) are generally 4.5m wide.

How heavy are the rolls of Rail Geosynthetics?

Roll weights vary between 27 to 320kg depending upon the product, roll width and length. Generally, rolls are installed using mechanical lifting equipment for large areas, smaller rolls or sheets cut from larger rolls can be installed manually.

How long will Geocomposites last? (Design life)

When designed, installed and maintained in accordance with the published literature most TERRAM Geotextiles and Geocomposites are sufficiently durable to achieve a design life of at least 100 years in most typical soil conditions. Please refer to DoP (Declaration of Performance) certificates for specific product grades which state the anticipated design life based on independent durability testing.

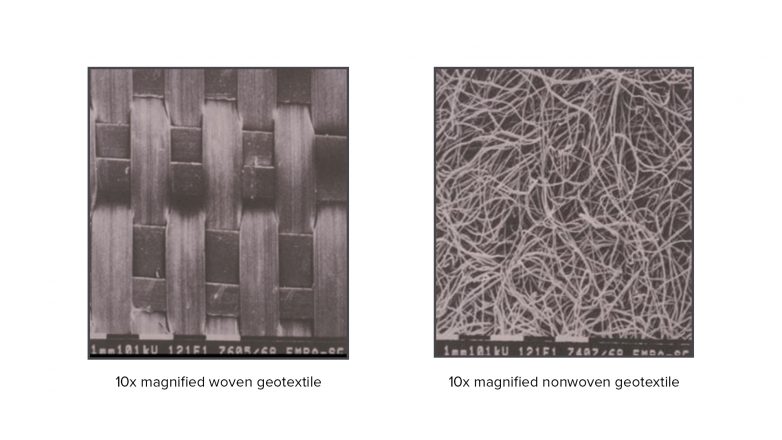

What is the difference between a woven and nonwoven (Terram) geotextile?

A woven geotextile is manufactured from continuous filaments or strips of synthetic material which are woven together to form a uniform sheet. A woven geotextile has a very uniform pore size which varies under load making them less suitable for filtering anything other than clean single sized soils/fills. Nonwoven geotextiles are a tangled web of fibres mechanically and/or thermally bonded together to form a non-uniform random web. Nonwoven TERRAM geotextiles have a wide range of pore sizes which make them ideally suited for filtering many different types of fill materials including well graded materials even under varying load conditions.

How important is the GSM (grams per SQM) weight of a Terram Geotextile?

The most important properties which affect performance of a geotextile are permeability, pore size, puncture resistance and tensile strength. GSM weight of a geotextile is a useful parameter for the purposes of internal quality control. TERRAM geotextiles often achieve the required functional performance at much lower weights compared to other geotextiles due to the exceptional quality control and state of the art manufacturing process.

What is a Terram Geotextile used for?

TERRAM geotextiles are predominantly used for separation and filtration of fill materials preventing intermixing and extending the service life of unbound materials. TERRAM geotextiles can also be used to provide puncture resistance and reinforcement in certain applications.

How do you joint Geotextiles?

Jointing TERRAM geotextiles can be achieved by overlapping, sewing, stapling or bonding. The simplest and most common jointing method is overlapping with overlap widths varying between 300mm and 1m depending upon the ground conditions and function of the geotextile. Please refer to TERRAM specification, design and installation guidance for more details.

What is the design life of a Terram Geotextile?

When designed, installed and maintained in accordance with the published literature most TERRAM geotextiles are sufficiently durable to achieve a design life of at least 100 years in most typical soil conditions. Please refer to DoP (Declaration of Performance) certificates for specific product grades which state the anticipated design life based on independent durability testing.

What is the coefficient of friction?

The typical coefficient of friction of a TERRAM geotextile is between 0.7 & 0.8 depending upon the amount of thermal treatment applied during production. Woven geotextiles generally tend to have a lower coefficient of friction between 0.5 and 0.8.

What are the roll sizes?

TERRAM geotextiles are available in rolls up to 6.0m wide and up to 175m long although the standard size roll for most common grades in the “T” range is 4.5m wide x 100m long.

What grade of Terram Geotextile do I need?

TERRAM T1000GT standard geotextile is the most commonly specified separation & filtration geotextile in the UK and is fit for most but not all conditions. Ground conditions (type of soil, strength and permeability), type & size of aggregate fill, size of compaction equipment, traffic loadings (weight & frequency) will all affect the grade of TERRAM geotextile required. Please refer to TERRAM specification, design and installation guidance for more details.

What is a Geotextile?

A permeable highly durable synthetic fabric general used in Civil Engineering and Building projects such as road and car park construction to stabilise loose soil and prevent erosion. TERRAM geotextiles are highly permeable nonwoven needle punched and thermally treated synthetic fabrics made from polypropylene used to separate, filter, reinforce, protect, or drain engineering soils. Typical uses include preventing intermixing of granular sub-base and subgrade layers, drainage and bedding materials. TERRAM geotextiles help reduce wastage/loss of expensive imported granular materials, improve structural performance and extend the life of the pavement/road/rail track.

What is a Geomembrane?

A geomembrane is an impermeable synthetic membrane liner used as a barrier for liquid or gas in both building and civil engineering applications. TERRAM do not manufacture geomembranes although certain TERRAM geocomposite products contain impermeable liners such as TERRAM PW3.1 and 1BZ. TERRAM’s sister company BPI Visqueen (also part of the Berry Global Group) are the UK’s market leading supplier of gas membranes for buildings and offer a wide range of membranes for other applications too.

What is pore size?

Pore size is a measurement of the gaps between the fibres within a permeable material such as a geotextile. TERRAM nonwoven geotextiles consist of a tangled web of randomly orientated polypropylene fibres, which result in a wide range of different size pores (gaps) ideal for filtering soil particles of different sizes, (gravels, sands and course silts) yet allowing the passage of water. Samples are tested in a laboratory to determine the range of pore sizes. To allow comparison between different geotextiles the apparent opening size (AOS) value is declared. The AOS is where 90% of the geotextile sample pores are of the same or smaller size (O90 value). The typical pore size allows designers to determine the suitability of a particular geotextile for filtering different grades of soil materials.

What is puncture resistance?

The relative ability of a geotextile to resist objects or stones from bursting or pushing through the material. TERRAM nonwoven geotextiles have a high puncture resistance essential to resist construction damage during installation and placing of fill material with compacting equipment. Woven geotextiles generally have much lower puncture resistance and often (unseen) damage occurs during installation resulting in reduced performance or failure in the longer term. Static puncture resistance consists of pushing a 50mm diameter plunger through the geotextile and is measured in kN (higher is better). Dynamic puncture resistance consists of dropping a cone into the geotextile and measuring the size of the hole in mm (lower is better).

What is permeability?

The relative ability of a geotextile to allow the passage of fluids or gas, usually water. TERRAM nonwoven geotextiles have very high permeability compared to similar weight woven geotextiles. The permeability of a geotextile is determined by recording the water flow rate in a laboratory test.

Geocomposites

Do you supply all rail drainage products?

Our distribution partners supply all rail drainage products including TERRAM geosynthetic materials. Please contact us for their contact details.

What are PADS numbers?

PADS (Parts and Drawing System) is Network Rail’s database of accepted products with numbers allocated to individual items or parts.

Are Terram products approved by Network Rail and TFL?

All TERRAM PW (Permanent Way), Standard Geotextiles hold Network Rail Acceptance certificates and have associated PADS numbers. TFL (Transport for London) and Network Rail require that all suppliers use of a qualification scheme called RISQS (Railway Industry Supplier Qualification Scheme). TERRAM (trading as Fiberweb Geosynthetics Ltd, part of the Berry Group) are registered with RISQS.

How do we cut the material of Rail Geosynthetics?

A4 Single layers of most TERRAM geosynthetic materials can be cut with sharp scissors or safety knives although regular changes of blades will be needed for long lengths. TERRAM Geocomposites such as PW4LA incorporate a reinforcing geogrid. The ribs of the geogrid mesh are square edged and up to 4mm thick, they can be cut with sharp shears or a disk cutter/angle grinder. Rolls can be trimmed with a petrol cut-off saw but suitable precautions should be taken to ensure the safety of the saw user and others in the vicinity. Wear appropriate personal protective equipment such as gloves and eye protection.

Do we overlap the material of Rail Geosynthetics?

The minimum overlap is 300mm but may be as much as 1.5m depending upon the ground conditions and product being installed. Please refer to the Network Rail Certificate of Acceptance and/or TERRAM specification, design and installation guidance for more details.

How wide are the rolls of Rail Geosynthetics?

TERRAM PW (Permanent Way) range varies between 1.9m and 4.0m wide. TERRAM standard geotextiles used for drainage trench lining (used alongside track) are generally 4.5m wide.

How heavy are the rolls of Rail Geosynthetics?

Roll weights vary between 27 to 320kg depending upon the product, roll width and length. Generally, rolls are installed using mechanical lifting equipment for large areas, smaller rolls or sheets cut from larger rolls can be installed manually.

What makes Terram Geocomposites better than alternatives?

TERRAM Geocomposites have been installed on numerous projects throughout the UK for decades with a proven track record. The extruded HDPE net drainage core has been designed to withstand extremely high compressive loads with minimal settlement and nearly 100% elastic recovery. Alternative Geocomposites such as those manufactured with cuspated cores collapse without recovery at a specific compressive load (crush) making them more susceptible to site damage during installation. Drainage composites with monofilament cores compress significantly under relatively low pressures which may result in surface settlement and significantly reduced flow rates.

What compressive loading will a Terram Geocomposite take?

All TERRAM Geocomposites have been tested with compressive loads between 20 and 200kPa to determine the flow rate capacity in accordance with EN ISO 12958. Flow rates at higher compressive loads are available on request.

How long will Geocomposites last? (Design life)

When designed, installed and maintained in accordance with the published literature most TERRAM Geotextiles and Geocomposites are sufficiently durable to achieve a design life of at least 100 years in most typical soil conditions. Please refer to DoP (Declaration of Performance) certificates for specific product grades which state the anticipated design life based on independent durability testing.

What is the right Geocomposite grade to use?

The type of Geocomposite and the grade will depend upon the site conditions and the application. Generally, TERRAM B1, 1B1, 1BZ, 1C1 are used for back of wall vertical drainage applications with ground water seepage. A higher grade Geocomposite may be required when higher ground water flow rates, higher pressures (due to depth of soil fill layers) and lower hydraulic gradients (Geocomposite laid close to horizontal) are expected.

How thick are the Geocomposites?

Between 4 and 10 mm depending on the grade of drainage net core, grade of geotextile or geomembrane. The thickness of the Geocomposite will decrease with increased weight of soil fill.

How do you install and join a Geocomposite?

TERRAM Geocomposites are manufactured in rolls varying from 2 to 4 wide and up to 100m long so are generally installed using mechanical lifting equipment for large areas, smaller rolls or sheets cut from larger rolls can be installed manually. When being used for back of wall drainage the Geocomposites can be held temporarily in place with a variety of fixings prior to backfilling with soil fill. For horizontal applications care must be taken to ensure the ground is flat or has a constant fall with no lumps or undulations to prevent ponding. All TERRAM Geocomposites are supplied with overlap edges which allow butt jointing and can be stapled or taped depending on the site conditions.

What are usual applications for Drainage Geocomposites and what flow rate do I need?

In most civil engineering or building applications the flow rate of ground water is quite low and often referred to as seepage for example back of wall drainage to prevent water pressure building up and pushing on a structure. In the cases of ground water seepage nominal flow rates are required in the drainage Geocomposites. Specialist applications such as landfill cell capping or basal drainage may require higher flow rates, have higher confining pressures due to the weight of fill and lower hydraulic gradients. In these specialist applications the correct grade of Geocomposite drain is selected based upon the anticipated site conditions, the relevant British, European or International design standard should be followed.

What is the flow rate?

The volume of water that can pass through the drainage core over a period of time. Usually flow rate is expressed in litres per m per second. Flow rate is affected by the pressure of the water (hydraulic gradient), the total weight of soil above (pressure) & the type of soil either side (simulated in the laboratory test by soft or hard platens).

What is a Geocomposite?

A relatively thin sheet of two or more materials with a plastic drainage core that provides a high flow path for gas & liquids (usually ground water in Civil Engineering applications). The drainage core is bonded to a geotextile(s) to filter out soil particles and/or a geomembrane on the other side to provide a fluid barrier. Geocomposites are often specified as a value engineered and more sustainable alternative to traditional drainage aggregate.

What is a Geomembrane?

A geomembrane is an impermeable synthetic membrane liner used as a barrier for liquid or gas in both building and civil engineering applications. TERRAM do not manufacture geomembranes although certain TERRAM geocomposite products contain impermeable liners such as TERRAM PW3.1 and 1BZ. TERRAM’s sister company BPI Visqueen (also part of the Berry Global Group) are the UK’s market leading supplier of gas membranes for buildings and offer a wide range of membranes for other applications too.

What is pore size?

Pore size is a measurement of the gaps between the fibres within a permeable material such as a geotextile. TERRAM nonwoven geotextiles consist of a tangled web of randomly orientated polypropylene fibres, which result in a wide range of different size pores (gaps) ideal for filtering soil particles of different sizes, (gravels, sands and course silts) yet allowing the passage of water. Samples are tested in a laboratory to determine the range of pore sizes. To allow comparison between different geotextiles the apparent opening size (AOS) value is declared. The AOS is where 90% of the geotextile sample pores are of the same or smaller size (O90 value). The typical pore size allows designers to determine the suitability of a particular geotextile for filtering different grades of soil materials.

Geocells

Can Terram Geocells be used to form retaining walls?

Yes, TERRAM geocells can be used to form retaining structures although this is not an application area that we actively promote in the UK market due to historic lack of demand. Different grades of TERRAM Geocells can be manufactured specifically for retaining structure applications but are made to order and there is a minimum order quantity.

Are Terram Geotextile Geocells permeable?

Yes, TERRAM Geotextile Geocells are manufactured from 100% permeable nonwoven geotextile fabric allowing ground water to pass through the cell walls rather than cascading over or underneath causing soil erosion.

Can I staple Geocells together?

Geocells can be stapled together using heavy duty galvanised metal staples, UV stabilised nylon cable ties or steel u-bars. Minimum 3 staples per joint at 25mm spacings. Please refer to the Geocell erosion control SDI for further details.

How many pins are needed per SQM when fixing a Geocell panel?

The general rule of thumb is 10 No. pins per TERRAM Geocell panel on a flat surface (Tree Root Protection) and 90 No. pins per panel on a slope (erosion control) however site specific conditions may require more or less.

What grade of Geocell do I need for Tree Root Protection?

25/10, 25/15 or 22/20 depending upon the strength of the underlying ground and the loading conditions. Please refer to the TERRAM Geocell Tree Root Protection SDI guide for more details.

How are Geocells delivered?

Flat packed, palletised and strapped.

How do I fix the Geocell panels?

The standard fixing method for a TERRAM Geocell on a slope is using an array of 500mm long 8mm diameter mild steel u-bars in soft to firm ground conditions. Installing a Geocell panel on an impermeable surface, hard or soft & loose sandy ground may require alternative fixings. The panels should also be fixed in anchor trenches at the top and bottom of the slope prior to filling.

Can I cut Geocell panels?

Terram Geocells are available in two variants: Terram geotextile geocell and Terram HDPE geocell. The Terram geotextile geocell is manufactured from strips of stiff but flexible nonwoven geotextile material that is chemically bonded at the joints to form honeycomb panels. These panels feature cells with strip widths (panel heights) ranging from 100mm to 200mm.

On the other hand, the Terram HDPE geocell is made of high-density polyethylene (HDPE) material. It also features honeycomb panels with cells ranging in strip widths (panel heights) from 100mm to 200mm. The inclusion of Terram HDPE geocell in our product range provides an alternative option for soil stabilisation and erosion control applications.

When working with Terram geocells, whether it is the geotextile geocell or the HDPE geocell, it is recommended to follow appropriate safety guidelines. Cutting single layers can be done by hand using safety knives or sharp scissors, with a downward action close to the joints. It is essential to wear suitable personal protective equipment, such as gloves and eye protection, to ensure safety during the installation process.

What is the maximum slope?

Up to 45 degrees (1:1 slope) depending upon the stability of the underlying soils.

What grade of Geocell do I need on a slope?

Generally, for slopes up to 30 degrees, grades 35/10 & 35/15 are recommended. For slopes between 30 and 45 degrees, grades 25/10, 25/15, 22/20 are suitable options. Additionally, with the recent addition of Terram HDPE Geocell to our product range, you can also consider the Terram HDPE Geocell option. Please see the Terram Geocell erosion control SDI (specification, design, and installation) guide for more details.

What is the size of the Terram Geocell panels?

Most of the Geotextile Geocell panels are approximately 7m x 5m when fully opened, the 200mm deep cells are approximately 6m x 3m. The panel weights are all below 25kg for manual handling reasons.

Terram HDPE Geocell panels are either 2.5m X 6.5 m or 2.5m X 8.3 m depending on the weld spacing. The panel weights are all between 26kg to 40kg for manual handling reasons.

General/Miscellaneous

Are the seminars available in webinar format?

Yes, recently TERRAM has been offering the seminars in webinar format, imparted online in your platform of preference.

Are Terram seminars available worldwide?

They are currently only available in the UK, although they are available in their webinar format worldwide.

Do you provide CPD certificates at the seminars?

Yes, CPD certificates are issued in pdf format via email to all those who attend.

Do you provide lunch at the seminars?

Yes, TERRAM will reimburse the cost for a light buffet style lunch.

What is the duration of the Technical Talks seminars?

45 min with 10 mins for questions & answers.

What are Terram Technical Talks?

TERRAM Technical Talks are CPD seminars primarily for designers/specifiers such as architects or engineers held at their offices at a time of their convenience. The seminars help gain insight into the geosynthetic industry, the uses and benefits of geosynthetics.

What are your sustainability goals?

As part of Berry Global, materials are at the heart of every product we manufacture. Our sustainability strategy, Impact 2025, highlights efforts in many areas:

- Lightweight products

- Design 100% of packaging to be reusable, recyclable, or compostable

- Achieve 10% recycled content across fast-moving consumer goods packaging

- Encourage the development of renewable materials

- Reduce greenhouse gases emissions by 25% by 2025 (vs 2016 baseline)

- Reduce landfill waste by 5% each year

- Partnering with organisations such as the Alliance to End Plastic Waste, Ellen McArthur Foundation, Operation Clean Sweep and EDANA.

Further information on Berry’s sustainability can be found here.

For decades TERRAM materials have provided sustainable solutions by reducing the amount and enhancing the performance of raw materials used in building, civil engineering and infrastructure construction. TERRAM’s range of ground reinforcement solutions such as gravel filled Bodpave 85 plastic porous paving systems are made from 100% recycled plastic waste and have a much lower carbon footprint compared to traditional surfaces like asphalt and concrete. Geosynthetic materials used beneath railtrack ballast provide a more sustainable method of construction offering cost, time and carbon savings by reducing excavation, reducing export of spoil & eliminating the need to import sand.

Independent Life Cycle Analysis of geosynthetic materials commissioned by the EAGM (European Association of Geoynthetic Manufacturers) clearly demonstrates the sustainability benefits of TERRAM geosynthetic materials. Follow this link below for more details:

Are your products manufactured in the UK?

The majority of TERRAM products are manufactured at the Berry Global production facility in Maldon, Essex, United Kingdom. Certain specialist components and products are imported from Europe & overseas where we are unable to source them from within the UK.

Do you use recycled materials in production?

TERRAM products contain up to 100% recycled materials depending upon the application, manufacturing process and CE marking requirements.

Do you supply directly to end customers/users?

TERRAM products are supplied by our distribution partners, we do not supply direct to end customers/users.

Do you include delivery charges?

We can provide delivered or ex works prices depending upon the customer’s needs.

What are your minimum order quantities?

We hold stocks of most common grades of TERRAM products based upon historic demand and forecasts provided by our distribution partners. The minimum order quantity for non-stock items will vary depending upon the type of products being manufactured and other orders being processed. Please contact our customer services team for further details.

Sustainability

What are your sustainability goals?

As part of Berry Global, materials are at the heart of every product we manufacture. Our sustainability strategy, Impact 2025, highlights efforts in many areas:

- Lightweight products

- Design 100% of packaging to be reusable, recyclable, or compostable

- Achieve 10% recycled content across fast-moving consumer goods packaging

- Encourage the development of renewable materials

- Reduce greenhouse gases emissions by 25% by 2025 (vs 2016 baseline)

- Reduce landfill waste by 5% each year

- Partnering with organisations such as the Alliance to End Plastic Waste, Ellen McArthur Foundation, Operation Clean Sweep and EDANA.

Further information on Berry’s sustainability can be found here.

For decades TERRAM materials have provided sustainable solutions by reducing the amount and enhancing the performance of raw materials used in building, civil engineering and infrastructure construction. TERRAM’s range of ground reinforcement solutions such as gravel filled Bodpave 85 plastic porous paving systems are made from 100% recycled plastic waste and have a much lower carbon footprint compared to traditional surfaces like asphalt and concrete. Geosynthetic materials used beneath railtrack ballast provide a more sustainable method of construction offering cost, time and carbon savings by reducing excavation, reducing export of spoil & eliminating the need to import sand.

Independent Life Cycle Analysis of geosynthetic materials commissioned by the EAGM (European Association of Geoynthetic Manufacturers) clearly demonstrates the sustainability benefits of TERRAM geosynthetic materials. Follow this link below for more details:

Are your products manufactured in the UK?

The majority of TERRAM products are manufactured at the Berry Global production facility in Maldon, Essex, United Kingdom. Certain specialist components and products are imported from Europe & overseas where we are unable to source them from within the UK.

Do you use recycled materials in production?

TERRAM products contain up to 100% recycled materials depending upon the application, manufacturing process and CE marking requirements.

Can Truckpave™ or Bodpave™ units be recycled?

Yes, both Truckpave and Bodpave units are made from polymers that can be recycled.

Original &

The Best