Robust Geotextiles

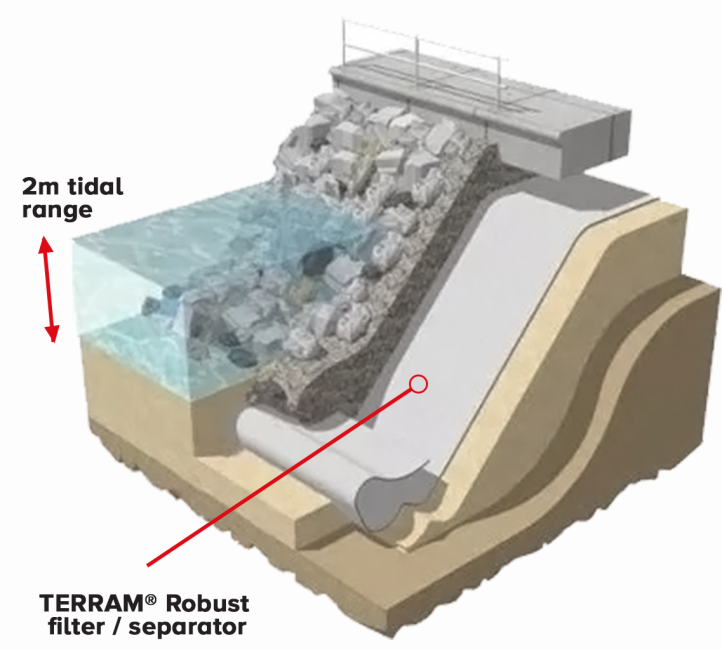

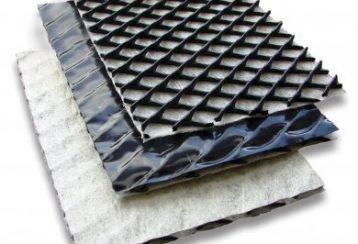

Heavy duty needle-punched geotextiles used to provide protection, separation and filtration functions in a variety of applications.

Frequently Asked Questions

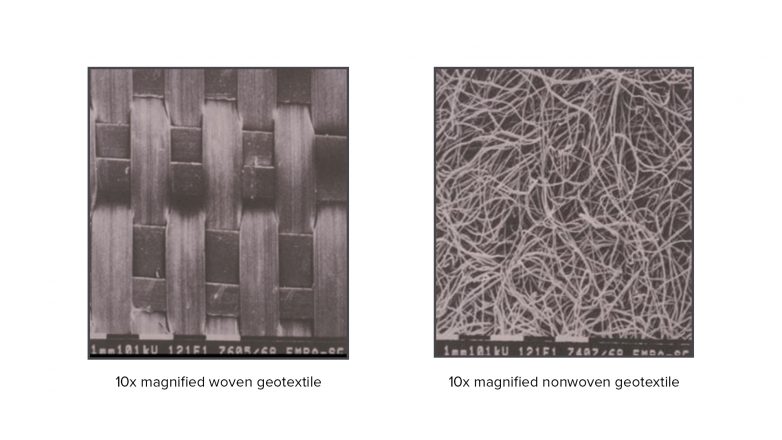

What is the difference between a woven and nonwoven (Terram) geotextile?

A woven geotextile is manufactured from continuous filaments or strips of synthetic material which are woven together to form a uniform sheet. A woven geotextile has a very uniform pore size which varies under load making them less suitable for filtering anything other than clean single sized soils/fills. Nonwoven geotextiles are a tangled web of fibres mechanically and/or thermally bonded together to form a non-uniform random web. Nonwoven TERRAM geotextiles have a wide range of pore sizes which make them ideally suited for filtering many different types of fill materials including well graded materials even under varying load conditions.

How important is the GSM (grams per SQM) weight of a Terram Geotextile?

The most important properties which affect performance of a geotextile are permeability, pore size, puncture resistance and tensile strength. GSM weight of a geotextile is a useful parameter for the purposes of internal quality control. TERRAM geotextiles often achieve the required functional performance at much lower weights compared to other geotextiles due to the exceptional quality control and state of the art manufacturing process.

What is a Terram Geotextile used for?

TERRAM geotextiles are predominantly used for separation and filtration of fill materials preventing intermixing and extending the service life of unbound materials. TERRAM geotextiles can also be used to provide puncture resistance and reinforcement in certain applications.

How do you joint Geotextiles?

Jointing TERRAM geotextiles can be achieved by overlapping, sewing, stapling or bonding. The simplest and most common jointing method is overlapping with overlap widths varying between 300mm and 1m depending upon the ground conditions and function of the geotextile. Please refer to TERRAM specification, design and installation guidance for more details.

What is the design life of a Terram Geotextile?

When designed, installed and maintained in accordance with the published literature most TERRAM geotextiles are sufficiently durable to achieve a design life of at least 100 years in most typical soil conditions. Please refer to DoP (Declaration of Performance) certificates for specific product grades which state the anticipated design life based on independent durability testing.

Original &

The Best