Case Studies

TRUCKPAVE – Wadlow Wind Farm (Cambridgeshire)

Overview

Project

Wadlow Wind Farm

Location

Near Newmarket, Cambridgeshire

Client

Renewable Energy Systems

Main Contractor

Forkers Ltd

Designer

JNP Group

SuDS Designer

McCloy Consulting

Product

TERRAM TRUCKPAVE 100

Product

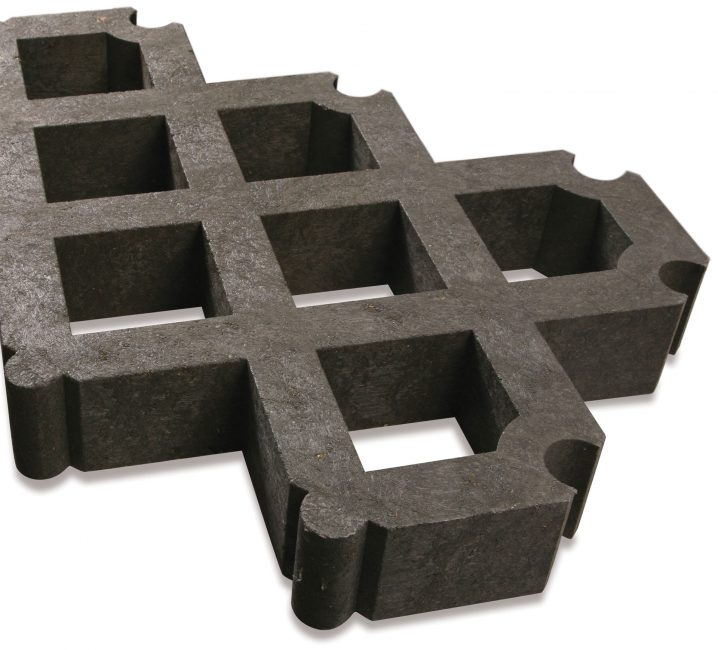

Truckpave Porous Pavers

Application Function

Ground Stabilisation

Market Sector

Renewable Energy

Product Solutions

TERRAM TRUCKPAVE units were installed at each of the 13 turbine locations to provide a porous and durable hardstanding area capable of withstanding HGV and crane loadings. Each TRUCKPAVE 600mm x 400mm unit contains 8No. 100mm x 100mm pockets which can be filled with either drainage aggregate or a seeded soil:sand mix to create a green grassed finish. The heavy-duty TRUCKPAVE units easily transfer loads downwards into the sub-base while preventing soil compaction in the growing pockets ensuring healthy growth of vegetation.

Original &

The Best