Erosion Control

Frequently Asked Questions

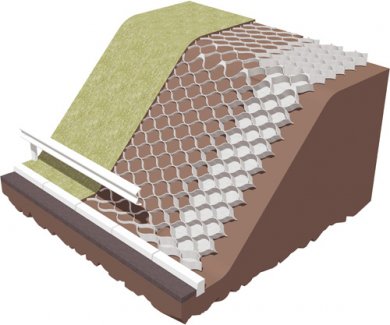

Can Terram Geocells be used to form retaining walls?

Yes, TERRAM geocells can be used to form retaining structures although this is not an application area that we actively promote in the UK market due to historic lack of demand. Different grades of TERRAM Geocells can be manufactured specifically for retaining structure applications but are made to order and there is a minimum order quantity.

What grade of Geocell do I need on a slope?

Generally, for slopes up to 30 degrees, grades 35/10 & 35/15 are recommended. For slopes between 30 and 45 degrees, grades 25/10, 25/15, 22/20 are suitable options. Additionally, with the recent addition of Terram HDPE Geocell to our product range, you can also consider the Terram HDPE Geocell option. Please see the Terram Geocell erosion control SDI (specification, design, and installation) guide for more details.

Are Terram Geotextile Geocells permeable?

Yes, TERRAM Geotextile Geocells are manufactured from 100% permeable nonwoven geotextile fabric allowing ground water to pass through the cell walls rather than cascading over or underneath causing soil erosion.

Can I staple Geocells together?

Geocells can be stapled together using heavy duty galvanised metal staples, UV stabilised nylon cable ties or steel u-bars. Minimum 3 staples per joint at 25mm spacings. Please refer to the Geocell erosion control SDI for further details.

How do I fix the Geocell panels?

The standard fixing method for a TERRAM Geocell on a slope is using an array of 500mm long 8mm diameter mild steel u-bars in soft to firm ground conditions. Installing a Geocell panel on an impermeable surface, hard or soft & loose sandy ground may require alternative fixings. The panels should also be fixed in anchor trenches at the top and bottom of the slope prior to filling.

Can I cut Geocell panels?

Terram Geocells are available in two variants: Terram geotextile geocell and Terram HDPE geocell. The Terram geotextile geocell is manufactured from strips of stiff but flexible nonwoven geotextile material that is chemically bonded at the joints to form honeycomb panels. These panels feature cells with strip widths (panel heights) ranging from 100mm to 200mm.

On the other hand, the Terram HDPE geocell is made of high-density polyethylene (HDPE) material. It also features honeycomb panels with cells ranging in strip widths (panel heights) from 100mm to 200mm. The inclusion of Terram HDPE geocell in our product range provides an alternative option for soil stabilisation and erosion control applications.

When working with Terram geocells, whether it is the geotextile geocell or the HDPE geocell, it is recommended to follow appropriate safety guidelines. Cutting single layers can be done by hand using safety knives or sharp scissors, with a downward action close to the joints. It is essential to wear suitable personal protective equipment, such as gloves and eye protection, to ensure safety during the installation process.

How are Geocells delivered?

Flat packed, palletised and strapped.

What is the size of the Terram Geocell panels?

Most of the Geotextile Geocell panels are approximately 7m x 5m when fully opened, the 200mm deep cells are approximately 6m x 3m. The panel weights are all below 25kg for manual handling reasons.

Terram HDPE Geocell panels are either 2.5m X 6.5 m or 2.5m X 8.3 m depending on the weld spacing. The panel weights are all between 26kg to 40kg for manual handling reasons.

Original &

The Best