Railways

Erosion Control

Frequently Asked Questions

What is a Geotextile?

A permeable highly durable synthetic fabric general used in Civil Engineering and Building projects such as road and car park construction to stabilise loose soil and prevent erosion. TERRAM geotextiles are highly permeable nonwoven needle punched and thermally treated synthetic fabrics made from polypropylene used to separate, filter, reinforce, protect, or drain engineering soils. Typical uses include preventing intermixing of granular sub-base and subgrade layers, drainage and bedding materials. TERRAM geotextiles help reduce wastage/loss of expensive imported granular materials, improve structural performance and extend the life of the pavement/road/rail track.

What is a Terram Geotextile used for?

TERRAM geotextiles are predominantly used for separation and filtration of fill materials preventing intermixing and extending the service life of unbound materials. TERRAM geotextiles can also be used to provide puncture resistance and reinforcement in certain applications.

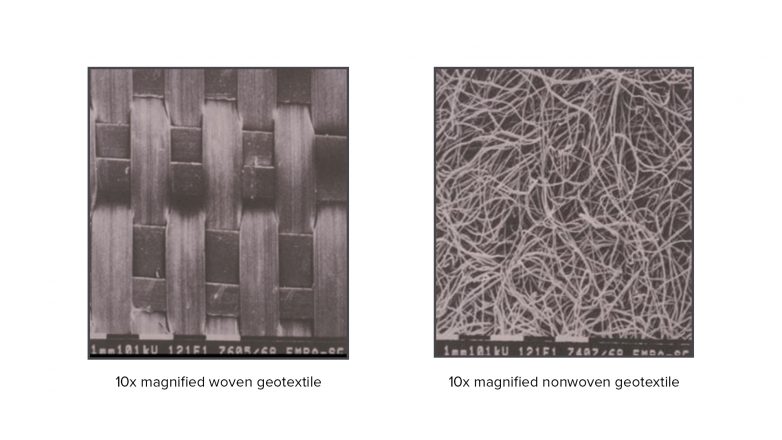

What is the difference between a woven and nonwoven (Terram) geotextile?

A woven geotextile is manufactured from continuous filaments or strips of synthetic material which are woven together to form a uniform sheet. A woven geotextile has a very uniform pore size which varies under load making them less suitable for filtering anything other than clean single sized soils/fills. Nonwoven geotextiles are a tangled web of fibres mechanically and/or thermally bonded together to form a non-uniform random web. Nonwoven TERRAM geotextiles have a wide range of pore sizes which make them ideally suited for filtering many different types of fill materials including well graded materials even under varying load conditions.

Are Terram products approved by Network Rail and TFL?

All TERRAM PW (Permanent Way), Standard Geotextiles hold Network Rail Acceptance certificates and have associated PADS numbers. TFL (Transport for London) and Network Rail require that all suppliers use of a qualification scheme called RISQS (Railway Industry Supplier Qualification Scheme). TERRAM (trading as Fiberweb Geosynthetics Ltd, part of the Berry Group) are registered with RISQS.

Are Terram Geotextile Geocells permeable?

Yes, TERRAM Geotextile Geocells are manufactured from 100% permeable nonwoven geotextile fabric allowing ground water to pass through the cell walls rather than cascading over or underneath causing soil erosion.

What grade of Geocell do I need on a slope?

Generally, for slopes up to 30 degrees, grades 35/10 & 35/15 are recommended. For slopes between 30 and 45 degrees, grades 25/10, 25/15, 22/20 are suitable options. Additionally, with the recent addition of Terram HDPE Geocell to our product range, you can also consider the Terram HDPE Geocell option. Please see the Terram Geocell erosion control SDI (specification, design, and installation) guide for more details.

Can Terram Geocells be used to form retaining walls?

Yes, TERRAM geocells can be used to form retaining structures although this is not an application area that we actively promote in the UK market due to historic lack of demand. Different grades of TERRAM Geocells can be manufactured specifically for retaining structure applications but are made to order and there is a minimum order quantity.

Can I cut Geocell panels?

Terram Geocells are available in two variants: Terram geotextile geocell and Terram HDPE geocell. The Terram geotextile geocell is manufactured from strips of stiff but flexible nonwoven geotextile material that is chemically bonded at the joints to form honeycomb panels. These panels feature cells with strip widths (panel heights) ranging from 100mm to 200mm.

On the other hand, the Terram HDPE geocell is made of high-density polyethylene (HDPE) material. It also features honeycomb panels with cells ranging in strip widths (panel heights) from 100mm to 200mm. The inclusion of Terram HDPE geocell in our product range provides an alternative option for soil stabilisation and erosion control applications.

When working with Terram geocells, whether it is the geotextile geocell or the HDPE geocell, it is recommended to follow appropriate safety guidelines. Cutting single layers can be done by hand using safety knives or sharp scissors, with a downward action close to the joints. It is essential to wear suitable personal protective equipment, such as gloves and eye protection, to ensure safety during the installation process.

Original &

The Best