Railways

Filtration & Separation

Frequently Asked Questions

What is a Geotextile?

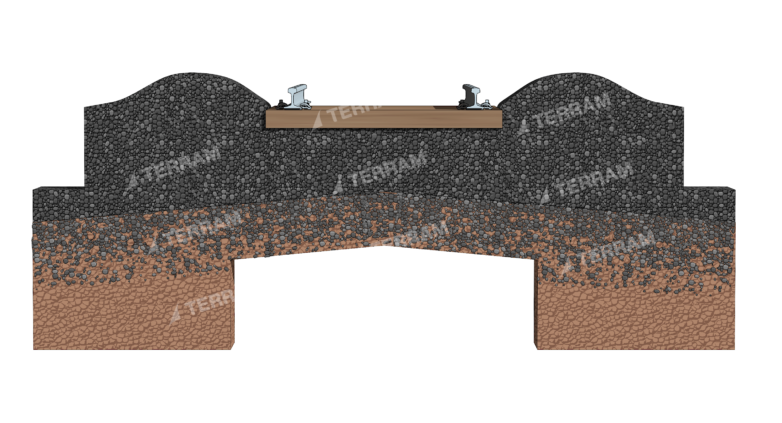

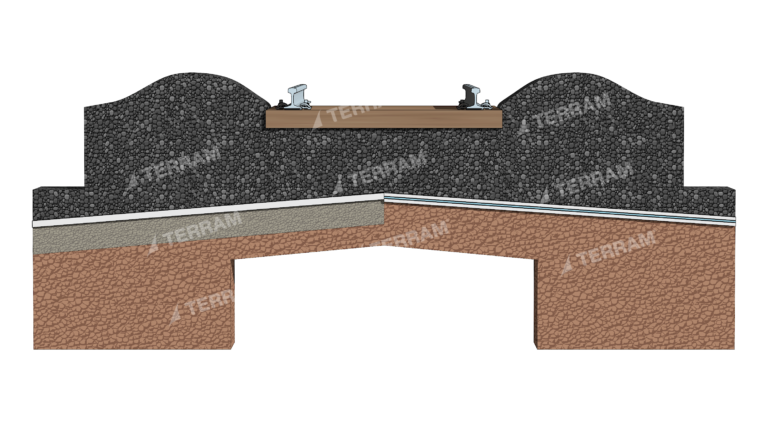

A permeable highly durable synthetic fabric general used in Civil Engineering and Building projects such as road and car park construction to stabilise loose soil and prevent erosion. TERRAM geotextiles are highly permeable nonwoven needle punched and thermally treated synthetic fabrics made from polypropylene used to separate, filter, reinforce, protect, or drain engineering soils. Typical uses include preventing intermixing of granular sub-base and subgrade layers, drainage and bedding materials. TERRAM geotextiles help reduce wastage/loss of expensive imported granular materials, improve structural performance and extend the life of the pavement/road/rail track.

What is a Terram Geotextile used for?

TERRAM geotextiles are predominantly used for separation and filtration of fill materials preventing intermixing and extending the service life of unbound materials. TERRAM geotextiles can also be used to provide puncture resistance and reinforcement in certain applications.

Are Terram products approved by Network Rail and TFL?

All TERRAM PW (Permanent Way), Standard Geotextiles hold Network Rail Acceptance certificates and have associated PADS numbers. TFL (Transport for London) and Network Rail require that all suppliers use of a qualification scheme called RISQS (Railway Industry Supplier Qualification Scheme). TERRAM (trading as Fiberweb Geosynthetics Ltd, part of the Berry Group) are registered with RISQS.

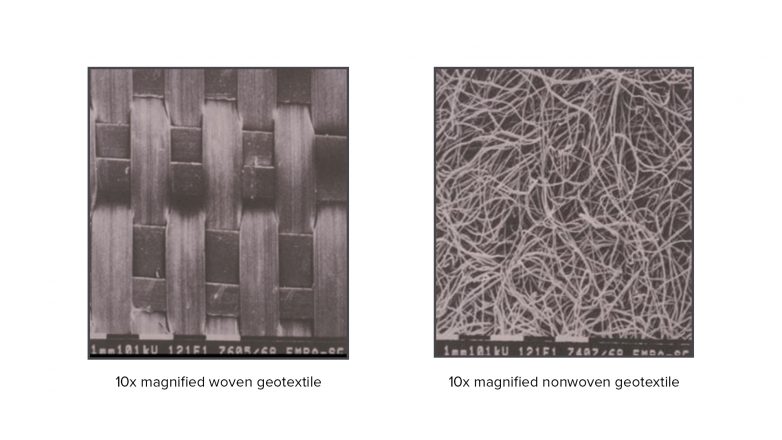

What is the difference between a woven and nonwoven (Terram) geotextile?

A woven geotextile is manufactured from continuous filaments or strips of synthetic material which are woven together to form a uniform sheet. A woven geotextile has a very uniform pore size which varies under load making them less suitable for filtering anything other than clean single sized soils/fills. Nonwoven geotextiles are a tangled web of fibres mechanically and/or thermally bonded together to form a non-uniform random web. Nonwoven TERRAM geotextiles have a wide range of pore sizes which make them ideally suited for filtering many different types of fill materials including well graded materials even under varying load conditions.

Do you supply all rail drainage products?

Our distribution partners supply all rail drainage products including TERRAM geosynthetic materials. Please contact us for their contact details.

Do we overlap the material of Rail Geosynthetics?

The minimum overlap is 300mm but may be as much as 1.5m depending upon the ground conditions and product being installed. Please refer to the Network Rail Certificate of Acceptance and/or TERRAM specification, design and installation guidance for more details.

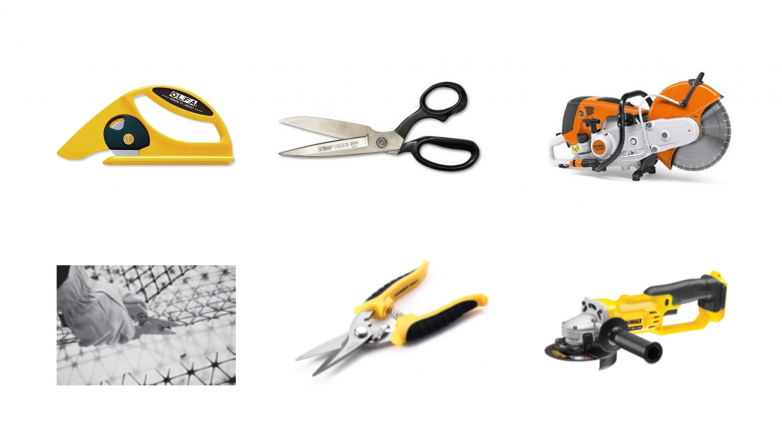

How do we cut the material of Rail Geosynthetics?

A4 Single layers of most TERRAM geosynthetic materials can be cut with sharp scissors or safety knives although regular changes of blades will be needed for long lengths. TERRAM Geocomposites such as PW4LA incorporate a reinforcing geogrid. The ribs of the geogrid mesh are square edged and up to 4mm thick, they can be cut with sharp shears or a disk cutter/angle grinder. Rolls can be trimmed with a petrol cut-off saw but suitable precautions should be taken to ensure the safety of the saw user and others in the vicinity. Wear appropriate personal protective equipment such as gloves and eye protection.

How heavy are the rolls of Rail Geosynthetics?

Roll weights vary between 27 to 320kg depending upon the product, roll width and length. Generally, rolls are installed using mechanical lifting equipment for large areas, smaller rolls or sheets cut from larger rolls can be installed manually.

How wide are the rolls of Rail Geosynthetics?

TERRAM PW (Permanent Way) range varies between 1.9m and 4.0m wide. TERRAM standard geotextiles used for drainage trench lining (used alongside track) are generally 4.5m wide.

Original &

The Best