Landfill

Stabilisation

Frequently Asked Questions

What is a Geocomposite?

A relatively thin sheet of two or more materials with a plastic drainage core that provides a high flow path for gas & liquids (usually ground water in Civil Engineering applications). The drainage core is bonded to a geotextile(s) to filter out soil particles and/or a geomembrane on the other side to provide a fluid barrier. Geocomposites are often specified as a value engineered and more sustainable alternative to traditional drainage aggregate.

What are usual applications for Drainage Geocomposites and what flow rate do I need?

In most civil engineering or building applications the flow rate of ground water is quite low and often referred to as seepage for example back of wall drainage to prevent water pressure building up and pushing on a structure. In the cases of ground water seepage nominal flow rates are required in the drainage Geocomposites. Specialist applications such as landfill cell capping or basal drainage may require higher flow rates, have higher confining pressures due to the weight of fill and lower hydraulic gradients. In these specialist applications the correct grade of Geocomposite drain is selected based upon the anticipated site conditions, the relevant British, European or International design standard should be followed.

What makes Terram Geocomposites better than alternatives?

TERRAM Geocomposites have been installed on numerous projects throughout the UK for decades with a proven track record. The extruded HDPE net drainage core has been designed to withstand extremely high compressive loads with minimal settlement and nearly 100% elastic recovery. Alternative Geocomposites such as those manufactured with cuspated cores collapse without recovery at a specific compressive load (crush) making them more susceptible to site damage during installation. Drainage composites with monofilament cores compress significantly under relatively low pressures which may result in surface settlement and significantly reduced flow rates.

What is a Geotextile?

A permeable highly durable synthetic fabric general used in Civil Engineering and Building projects such as road and car park construction to stabilise loose soil and prevent erosion. TERRAM geotextiles are highly permeable nonwoven needle punched and thermally treated synthetic fabrics made from polypropylene used to separate, filter, reinforce, protect, or drain engineering soils. Typical uses include preventing intermixing of granular sub-base and subgrade layers, drainage and bedding materials. TERRAM geotextiles help reduce wastage/loss of expensive imported granular materials, improve structural performance and extend the life of the pavement/road/rail track.

What is a Terram Geotextile used for?

TERRAM geotextiles are predominantly used for separation and filtration of fill materials preventing intermixing and extending the service life of unbound materials. TERRAM geotextiles can also be used to provide puncture resistance and reinforcement in certain applications.

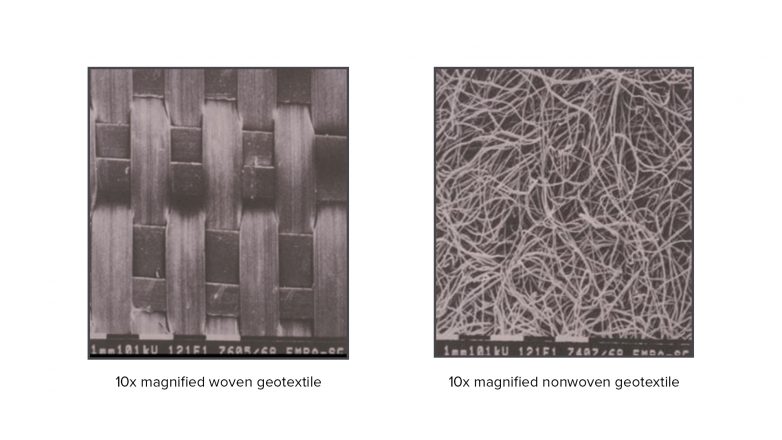

What is the difference between a woven and nonwoven (Terram) geotextile?

A woven geotextile is manufactured from continuous filaments or strips of synthetic material which are woven together to form a uniform sheet. A woven geotextile has a very uniform pore size which varies under load making them less suitable for filtering anything other than clean single sized soils/fills. Nonwoven geotextiles are a tangled web of fibres mechanically and/or thermally bonded together to form a non-uniform random web. Nonwoven TERRAM geotextiles have a wide range of pore sizes which make them ideally suited for filtering many different types of fill materials including well graded materials even under varying load conditions.

What is the design life of a Terram Geotextile?

When designed, installed and maintained in accordance with the published literature most TERRAM geotextiles are sufficiently durable to achieve a design life of at least 100 years in most typical soil conditions. Please refer to DoP (Declaration of Performance) certificates for specific product grades which state the anticipated design life based on independent durability testing.

Original &

The Best